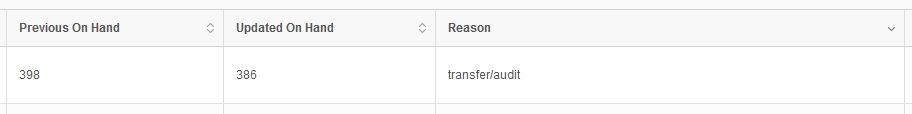

When operating a warehouse, you will likely end up moving around plenty of stock and inventory. While a good portion of this will be shipped and removed from the warehouse entirely, a good amount will also be moved around within the warehouse. The most common is from a receiving location to its final storage location. However, there are also a large number of minor inventory adjustments such as a broken storage location or consolidating inventory, as the picker has the option to identify the reason for the move on their device, which will then show in the inventory report:

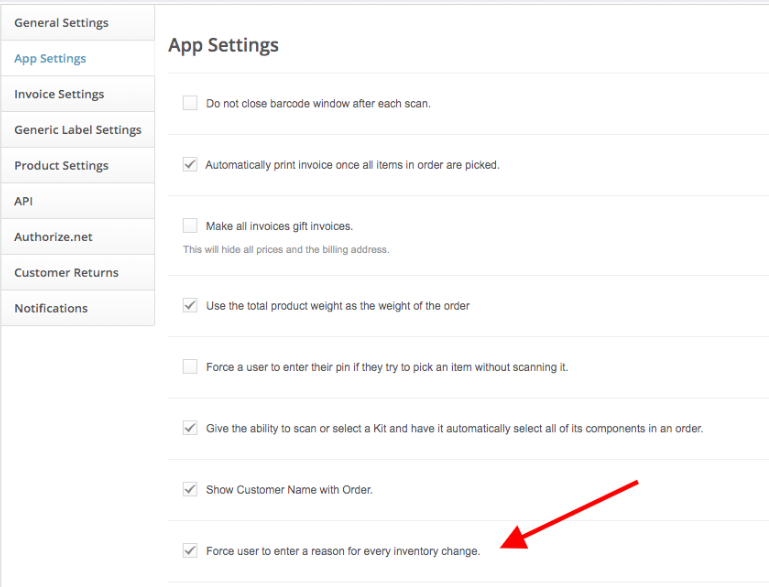

You can also force pickers to enter a reason when making an inventory adjustment with the following setting: